GrT, GrAT, GrAK

● GrT-1250/71 ● GrT-1600/50

● GrAT-450/67 ● GrAK-85/40

● 2GrT-1600-50 ● 12Gr-8T

☑ Seals operate as bagger pumps, pumping coal or ash slurry at thermal power plants running on coal. There is also the experience for GrAK pumps, pumping the milk of lime.

☑ Because of the high abrasiveness of the pumped slurry, the seal is designed with intaking of washing liquid before floating stuffing box. Lantern ring whether incorporated into the seal housing, or is installed separately.

☑ Radial mobility of the stuffing box can significantly extend the life of the pump (until the time you have to replace the impeller and (or) a protective shaft sleeve), as it allows to compensate shock loads on the shaft of the impeller side. Over time the impeller imbalance increases, so the shock loads become stronger. However, in contrast to conventional seals, leakage is not increased and consequently the abrasive slurry along with leaks does not pollute the packing, otherwise it would cause the fast deterioration and wear of protective shaft sleeve.

☑ Material of metal parts of seal is carbon steel with zinc or nickel-plated (warranty period - 1 year).

☑ Sealing devices are available in an assembly and include protective sleeve of the shaft. Any pump modifications are not required. Gland packing is braid thermally expanded graphite.

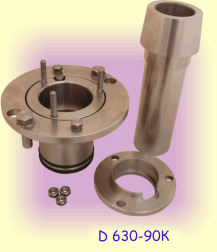

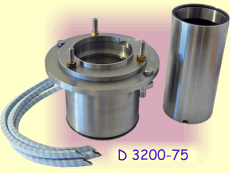

D, NDS, NDN, NDV, CN

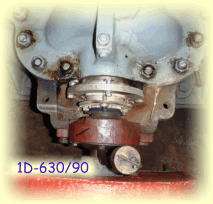

● D 630-90K (8NDV-Х) ● 1D 630-90

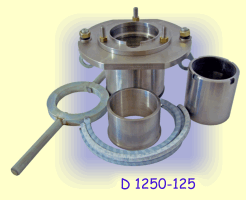

● D 1250-65 ● D 1250-125 ● D 2500-62

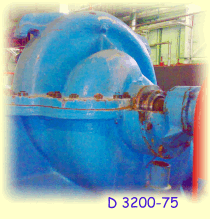

● D 2000-100 ● D 3200-75 ● D 4000-95

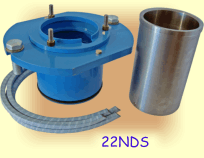

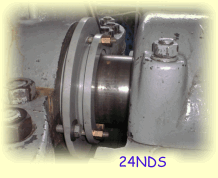

● D 6300-27 ● 14D-6 ● 22NDS ● 24NDS

● 18NDS ● 24NDN ● 6NDS-60 ● D 250-50

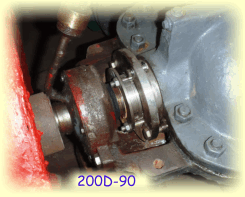

● 6NDV-X ● 200D-60 ● 200D-90

● 300D-90 ● CN 3000-197 ● 10NМКх2

● CN 400-105 (3V200х2)

● CN 400-210 (3V200х4)

☑ Seal does not need the cooling fluid and the lantern ring is not used.

☑ Floating stuffing box is able to neutralize the shaft misalignment up to 1.5mm on the radius and whlie the pump is running the stuffing box is tracking any shaft fluctuations in radial direction up to 0.5mm on the radius.

☑ It is used the packing made of braid thermally expanded graphite. Rubber O-rings are made of rubber compound with high heat and radiation resistance.

☑ Options available for metal parts of seal are: 1) corrosion-resistant steel 321 (AISI) (4-year warranty), or carbon steel with zinc or nickel-plated (1 year warranty period).

☑ Sealing devices are available in an assembly and include protective sleeves of the shaft. Any pump modifications are not required.

☑ The seals operate at thermal power plants, at heat and power plants, at nuclear power plants, at district heating networks, at coke-chemical and ore mining industrial complexes, at steel-producing factories, at city water supply systems.

☑ The seal operates on the pumps pumping technical, network, drinking water, and in case of D 630-90K pump it used for pumping the boron concentrate to a cooling waste nuclear fuel pond at nuclear power plants.

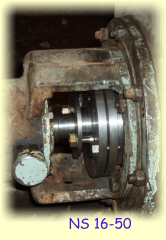

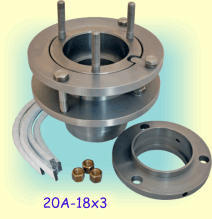

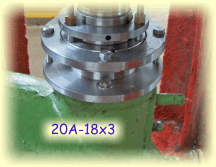

NKu, A, NS, NK, HPK series

● 1NKu 630/80 ● NKu 140М-а

● NKu 250/32 ● 10NKu-7-2

● 20A-18х3 ● 24A-18х1

● NS 16-50 ● NK-200-500/540

● HPK-E4 350-500

☑ Seal has a stuffing box that can roll easily on bearing balls or on thickened rubber O-ring and provide the dynamic compensation of the radial oscillations of a rotating shaft (up to 0.5mm per side) and the static self-centering (up to 1mm or 1.5mm per side).

☑ Made of steel 321 (AISI) (warranty period is 4 years).

☑ The seaing devices operate at nuclear power plants, at thermal power plants, at heat and power plants, at district heating networks, at metallurgical and coke-chemical factories.

☑ The seals installed on the pumps that are used as recirculating (NKu), fire (A), drainage (NS), network (NK) or hot water circulating (HPK).

for which self-aligning stuffing boxes are produced (part 2)

This part introduces self-centering sealing device developed and manufactured by private enterprise "Energotehnika", Kiev, for horizontal general industrial pumps kind of D, NDS, NDN, NDV, CN, recirculation pumps type of NKu, cradle-mounted NK pumps, vertical artesian pumps type of A, self-priming NS pumps, hot water circulating pumps type HPK and cradle-mounted pumping slurry pumps type of GrT, GrAT, GrAK.

Above-listed pumping equipments are produced at the following plants respectively:

◎ NASOSENERGOMASH Sumy JSC (D, CN, NS pupms);

◎ "Yuzhgidromash" Berdyansk (NKu pumps);

◎ "Energomash (Sisert) Uralhydromash" CJSC (CN, D pumps);

◎ Grundfos (NK pumps);

◎ VIPOM Bulgaria (D pumps);

◎ "HMS Pumps" OJSC Livgidromash (D pumps);

◎ "Bobruisk Machine Building Plant" (GrT, GrAT, GrAK pumps);

◎ "SVESSA PUMP PLANT" PJSC (A pumps);

◎ The KSB Group (HPK pumps).